High-Efficiency Energy Production, Minimal Water Consumption

Solid-Phase Anaerobic Digestion (SSAD), part of Mass Bioenerji’s technology portfolio, is an innovative approach to organic waste management. Unlike traditional liquid systems, this technology is an innovative system that produces biogas by directly processing waste with high dry-matter content. While conventional systems are often limited to 10-12% dry matter ratios, SSAD technology can efficiently process waste with very high ratios, such as 20-55%.

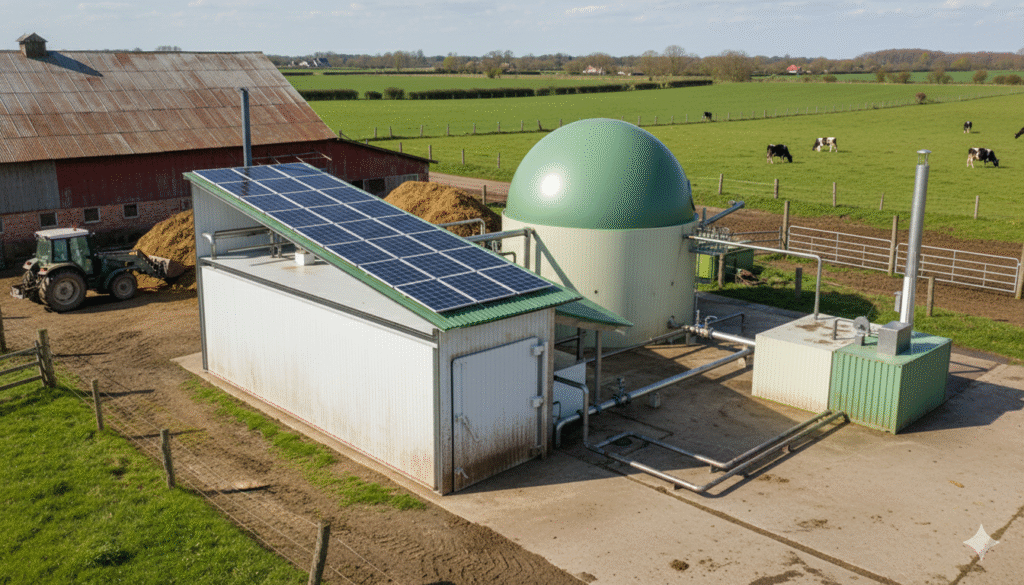

One of the most significant differences of this approach is that it does not require the complex mechanical mixers needed by liquid systems and stands out with its “garage-type” reactor design. This method, specially optimized for agricultural waste, offers an effective and flexible solution in the transition from waste to energy with its high methane yield and capacity.

What is the Key Difference from Traditional Systems?

Traditional biogas systems require large amounts of water to process waste and typically operate at a 10-12% dry matter ratio. SSAD technology, however, can directly process organic waste with very high dry matter content, such as 20-55% (Our technical capacity is suited to operate at 25-35%), without the need for water addition. This means we can process a wider range of waste (e.g., agricultural waste, municipal solid waste) with less need for pre-treatment.

How Does It Work? Garage-Type Efficiency

Our SSAD system stands out with its “garage-type” reactor design and, unlike traditional liquid systems, does not require complex mechanical mixers. The process operates on the principle of percolation:

Loading Phase: Organic waste is loaded into the reactors.

Percolate Recirculation: Leachate (percolate) is continuously recirculated within the reactor.

Even Distribution: This recirculation evenly distributes heat, moisture, and the biogas-producing microorganisms throughout the entire waste mass.

Efficiency and Resource Conservation: This closed loop ensures highly efficient biogas production with minimal water consumption and conserves valuable water resources.

Key Advantages of SSAD Technology

Zero Odor and Full Emission Control: Since the system operates in a completely enclosed structure, the formation of bad odors during operation is entirely prevented, and emissions are kept under control.

High Methane Yield: Thanks to the controlled process, high methane yield and high biogas capacity are achieved.

Minimal Water Consumption: The closed-loop percolation system minimizes water requirements, reducing operational costs and conserving resources.

Low Maintenance Requirement: The absence of moving parts, such as mechanical mixers, reduces maintenance costs and the risk of breakdowns.

Smart and Scalable System: Our facilities have a modular, scalable structure, and the entire process can be remotely monitored and managed via IoT-based smart control

Application Areas

Unlike traditional liquid systems, SSAD technology addresses a very wide range of inputs thanks to its capacity to process waste with high dry-matter content (25-35%). This technology is “specifically optimized for agricultural waste,” such as straw, corn cobs, and animal manure.

At the same time, it is an ideal solution for municipal organic waste (kitchen and garden waste), which is one of the biggest challenges for municipalities. In addition, industrial organic wastes, such as fruit and vegetable processing residues from food production facilities and waste from the meat and dairy industries, are also converted into energy with high efficiency in this system.