Upcycling of Waste and Maximum Recovery

Microwave Pyrolysis is a critical part of our integrated technology portfolio and our circular economy model. This technology targets the maximum energy and value recovery from waste by enabling the “upcycling” of organic carbon. Its main purpose is to provide an ideal solution for processing resilient organic materials remaining after the SSAD (biogas) and composting processes, or other special waste streams.

Difference from Traditional Methods: Why Microwave?

Pyrolysis is the process of decomposing organic carbon in an oxygen-free environment at high temperatures. While traditional pyrolysis systems perform this heating from the outside in (conventionally), our advanced reactors carry out this process assisted by microwaves. This integration provides a much more efficient and superior process for energy recovery from waste compared to classic pyrolysis methods.

High Energy Conversion Rate: Microwave technology allows us to achieve a 30-40% higher energy conversion rate compared to classic pyrolysis methods. This means we obtain more energy and valuable products (biochar, bio-oil) from the same amount of waste.

Speed and Product Quality: Traditional systems heat the waste from the outside, which causes slow and uneven heating. Microwaves, however, heat the entire material simultaneously and from within. Thanks to this “uniform heating” (evenly distributed heating), the process time is much shorter than traditional methods. This fast and controlled process ensures a higher quality end-product.

Energy-Efficient Operation: Unlike traditional systems, there is no need to heat the entire reactor mass from the outside; the energy is focused directly on the waste material. This makes microwave-assisted pyrolysis a more energy-efficient operation compared to conventional systems.

Key Advantages of Pyrolysis Technology

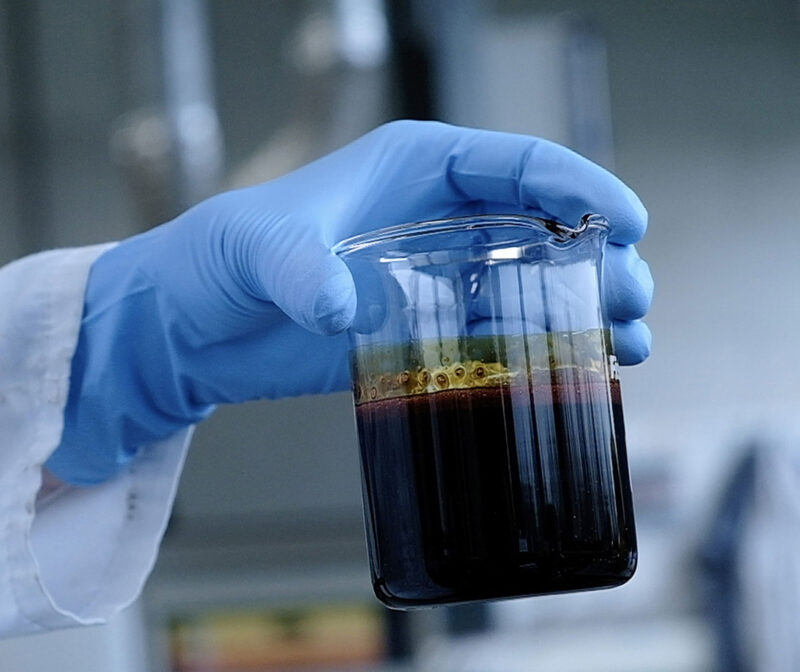

Multiple Valuable Product Output: This technology converts organic waste into multiple valuable end-products: Biochar (soil conditioner), Bio-oil (biofuel), and Synthesis Gas (Syngas) (for energy production).

High Carbon Sequestration Capacity: It provides over 95% carbon sequestration efficiency, especially thanks to biochar production. This high capacity actively contributes to the fight against climate change.

Energy-Efficient and Eco-Friendly Operation: Microwave assistance provides a more efficient operational process with less energy consumption.

Continuous Development (R&D): We are constantly improving our technology in microwave pyrolysis optimization through our active R&D efforts.

Application Areas

Microwave Pyrolysis technology offers an ideal upcycling solution, especially for resilient organic materials remaining after passing through our other integrated systems (SSAD and composting), or for other special waste streams.

Furthermore, it is an excellent technology for specific inputs like forestry and landscaping waste. Tree trimmings, sawdust, bark, and other wood wastes are processed with high efficiency in this system and are particularly suitable for producing biochar, a valuable end-product with high carbon sequestration capacity.